KPR-8356 AC Compressor rau Honda City 1.5L Haum OE 38800RSHE010

Nrog ntau tshaj 16 xyoo kev txawj ntse, KPRUI muaj keeb kwm nplua nuj hauv a/c compressors.

Yog tias koj xav tau Honda city lub tsheb ac compressor nqe, thov hu rau peb.

Lub tshuab cua txias (A/C compressor) ua dab tsi?

Ib yam li lub plawv hauv tib neeg lub cev, lub compressor ncig lub cev txoj sia, hauv qhov no yog cov refrigerant, uas yog qhov tseem ceeb rau kev ua haujlwm zoo ntawm lub tshuab cua txias (A/C). Nws txav cov roj los ntawm lub evaporator, nias nws, thiab xa nws ntawm qhov siab thiab kub siab mus rau lub condenser, qhov chaw nws hloov mus ua cov roj txias uas txias cov huab cua hauv lub tsheb. Vim li no, koj yuav xav tau lub compressor zoo uas tau lees paub, tsim los xa lub sijhawm sai dua rau kev nplij siab thiab kev siv roj zoo dua thiab cov pa phem.

Kev Tswj Xyuas Koj Lub Honda City AC Compressor

Zoo siab, kev saib xyuas koj lub tshuab cua txias A/C yog qhov tsawg heev thiab suav nrog cov hauv qab no:

1. Siv lub tshuab compressor tsis tu ncua kom tag nrho cov khoom ntawm lub tshuab muaj roj nplua nyeem zoo.

2. Ntxiv roj rau koj cov roj txias kom paub tseeb tias lub tshuab cua txias muaj qhov siab txaus.

3. Ntxuav thiab zawm cov siv tsav tsheb raws li qhov tsim nyog.

4. Ua qhov kev kuaj xyuas hluav taws xob ntawm cov qhov hloov thiab cov sensors, nrog rau lub fuse, relay, thiab coil ntawm EM clutch.

Cov thawv ntim khoom ib txwm muaj lossis cov thawv xim tshwj xeeb.

Lub khw sib dhos

Kev cob qhia ua haujlwm

Mes lub cockpit

Thaj chaw ntawm tus neeg xa khoom lossis tus neeg xa khoom

Kev Pabcuam

Kev pabcuam tshwj xeeb: Peb muaj peev xwm ua tau raws li qhov xav tau ntawm peb cov neeg siv khoom, txawm tias yog ib pawg me me ntawm ntau hom, lossis kev tsim khoom loj ntawm OEM kev hloov kho.

OEM/ODM

1. Pab cov neeg siv khoom los tsim cov kev daws teeb meem sib phim.

2. Muab kev txhawb nqa rau cov khoom.

3. Pab cov neeg siv khoom daws cov teeb meem tom qab muag.

1. Peb tau tsim cov tshuab cua txias rau ntau tshaj 15 xyoos.

2. Kev teeb tsa qhov chaw teeb tsa kom raug, txo qhov sib txawv, yooj yim sib sau ua ke, kev teeb tsa hauv ib kauj ruam.

3. Kev siv cov hlau zoo, qib siab dua ntawm kev nruj, txhim kho lub neej kev pabcuam.

4. Txaus siab, kev thauj mus los zoo, txhim kho lub zog.

5. Thaum tsav tsheb ntawm qhov ceev ceev, lub zog nkag mus rau hauv lub cav yuav txo qis thiab lub nra hnyav ntawm lub cav yuav txo qis.

6. Kev ua haujlwm du, suab nrov qis, kev co me me, lub zog pib me me.

7. 100% kev tshuaj xyuas ua ntej xa khoom.

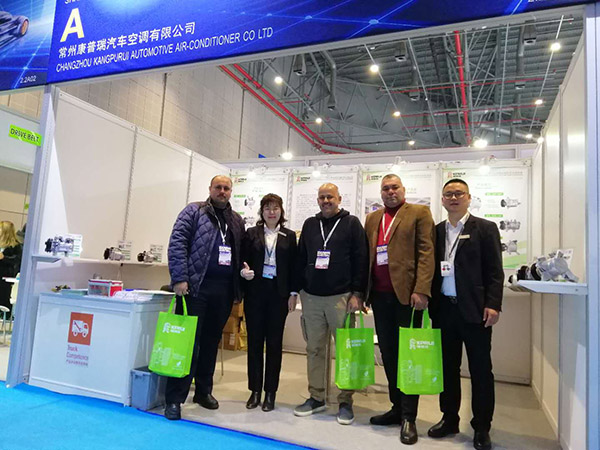

AAPEX hauv Asmeskas

Automechanika Shanghai 2019

CIAAR Shanghai 2019